In retrospect: It wasn’t until I started playing around with RFID technologies that I got exposed to the retail industry. At the time I was still at SAP and we were experimenting with “Big Data” producers. RFID produces a LOT of data (albeit a lot of noise too). As the product lead I was more interested in problems this technology could solve which leant itself nicely to the retail industry. What resulted was a beautiful proof of concept created that was built using Intel RFID antenna hardware that illustrated 6 strong retail use cases (detailed in the blog below). In addition to working with RFID and retail, this initiative also gave me exposure to hardware partnerships and sales, working to find pilot accounts within the SAP global enterprise retail customer landscape.

Does RFID have a future in retail? Yes until computer vision gets better. RFID has been around for a long time but it still lacks 2 main challenges to mass adoption: cost & complexity. Cost for hardware and tagging every individual item cuts retail margins. Layer in adding another inventory system into an existing legacy landscape for systems of record adds to overall system complexity. But clearly RFID is gaining in grocery (Amazon Go), so perhaps the race is still on.

ORIGINAL POST FOLLOW FROM NOVEMBER 10, 2016

(https://blogs.sap.com/2016/11/10/can-iot-really-help-retailers/)

“The system says that there are 3 shirts in the store, but…”

How many times have you gone into a store and asked an associate to look-up something, and after the look-up (which can also take some time), the associate scratches their head and claims it’s in the store according to the system, but they still can’t find it? Or even worse, you researched online and came into the store expecting to buy something and it’s not there? I have spent the better half of the year talking to retailers about inventory accuracy and I have discovered that everyone has a magic number. You know, that number in the system that you need to see in order to BELIEVE that at least one of the items is actually there.

Why is inventory accuracy so difficult to achieve?

Inaccurate inventory is a problem that has plagued retailers for ages and you may be shocked to find out that average inventory accuracy is only around 65%. A lack of inventory accuracy produces symptoms in stores such as over-stocking and out-of-stocks, which are actually quite costly for retailers (over $1 trillion a year).

Think about the dynamic nature of retailing. Throughout a day, a store performs many different operations other than selling in the store (which is why after-the-fact point-of-sale (POS) data is never good enough). There are store transfers. There are goods to be received that haven’t been accounted for yet. There is shrink (permanently missing items). There are e-commerce sales. The list goes on.

Improving inventory accuracy with the Internet of Things (IoT)

How can IoT be used to improve inventory accuracy? First we can digitize the inventory. Let’s define the Things as sensors on individual items in inventory (like 1 shirt, or 1 shoe, or 1 can). These sensors can vary from a wide range of technology like beacons, RFID tags, or shelf liners that can stream raw data about inventory presence. For example, if I take something off a shelf, the shelf can send a message that an item has been moved off the shelf. Or if I take a shirt into a dressing room, the shirt can send a message that it has moved into another area. Now imagine all these items talking, constantly sending state updates per millisecond to a dynamic edge processing server sitting in a store.

What immediately happens is your inventory accuracy level rises as you are given inventory counts that are timelier than cycle counts (physical counting) could ever create. This can be done quickly, run on minimal hardware, and independent from existing systems and network connections. But is that truly retailer ROI for IoT? Knowing in-store inventory levels for a particular item is not useful if you can’t act on it. In fact you might argue an associate could easily tell you a shelf is empty just by looking at it rather than investing in IoT technology to tell you.

More than IoT data – Business of Things

But what if you could combine your minimum quantity rules from SAP with an automated purchase order requisition from the store based on the total in-store count for an item? You could potentially avoid stock-outs from ever happening, not from just live inventory counts, but with combined intelligence at the store level. Or what if you could automate receiving so associates don’t need to manually scan everything, highlighting discrepancies between what was received versus the original purchase requisition automatically, freeing the associate up to make sales in the store front?

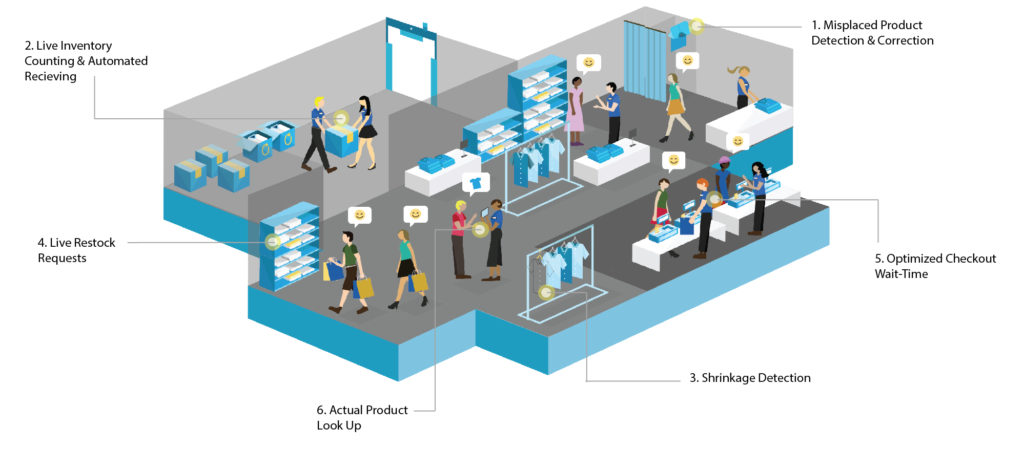

Here are 6 use cases we have identified where IoT combined with dynamic edge processing can help retailers:

Retail Reality Check

We have the technology today to achieve this and we have worked on many edge processing scenarios across various industries, including retail. But is retail really ready for it? A lot of the retailers I have spoken to are just starting to dip their toe into the IoT water. They’re interested in simple use cases around improving efficiency with real-time in-store data to build the ROI case. I can appreciate that approach. But I truly believe it won’t be until we marry the insights collected at the store with the business intelligence at the headquarters that IoT will start to make real gains in retail. When retailers are ready, we will be waiting.